Home > Blog > Mastering > Mastering Formats

In an age dominated by digital music, the resurgence of vinyl records has sparked renewed interest in the art of audio mastering for this beloved analog format. This article delves into the intricacies of vinyl mastering, highlighting its unique challenges and explaining why a tailored approach is crucial for achieving optimal sound quality on your turntable.

Audio mastering for vinyl is a specialized process of preparing recordings for reproduction on vinyl records. Unlike digital formats, vinyl imposes unique constraints, like limited dynamic range, frequency response, and groove spacing. Mastering engineers must consider the RIAA EQ curve, minimize distortion, and maintain optimal playback levels.

Audio mastering for vinyl requires a unique set of skills and techniques to optimize sound quality in this classic analog format. Discover the captivating art behind vinyl mastering and unveil the secrets to achieving the warm, authentic sound that vinyl enthusiasts crave.

Table Of Contents

1. Introduction To Vinyl Records

2. The Importance Of Audio Mastering For Vinyl

3. The Vinyl Mastering Process

4. Key Vinyl Mastering Tools And Techniques

5. Limitations And Challenges Of Vinyl Recordings

6. The Role Of Test Pressings In Vinyl Distribution

7. Vinyl Pressing Plants And Vinyl Quality Control

8. Proper Vinyl Storage, Cleaning And Handling

9. Vinyl Mastering: Reviving Analog Audio

1. Introduction To Vinyl Records

Vinyl records, once the primary medium for music consumption, have made a remarkable comeback in recent years, captivating a new generation of audiophiles who appreciate the format’s warmth and tangibility.

Emerging in the early 20th century, vinyl records were gradually overshadowed by the advent of CDs and digital music platforms. However, their resurgence has reignited a passion for the tactile and nostalgic experience they offer, as well as the unparalleled sound quality attributed to the analog format.

Vinyl records have a rich history, tracing their roots back to the late 19th century with the invention of the phonograph.

The modern vinyl record, as we know it, gained popularity in the 1940s with the introduction of the 33⅓ RPM long-playing (LP) format and the 45 RPM single. Vinyl records dominated the music industry for decades, serving as the primary medium for music distribution and consumption until the 1980s.

With the advent of new technologies such as cassette tapes, compact discs (CDs), and later, digital music platforms, vinyl records faced a decline in popularity as consumers gravitated toward the convenience of these emerging formats.

However, in the late 2000s, vinyl records experienced an unexpected resurgence, fueled in part by a desire for a more tangible, nostalgic, and personal connection to music.

The renaissance of vinyl records has been driven by several factors, including the appreciation for their unique sound quality, the appeal of large album artwork, and the ritualistic experience of playing a record.

Audiophiles argue that the analog nature of vinyl records delivers a warmer, more authentic sound that captures the nuances of a recording more faithfully than digital formats. Furthermore, the act of collecting and engaging with physical music media has become a cherished pastime for many enthusiasts.

In recent years, vinyl sales have continued to grow, with new pressing plants opening and established artists releasing their albums on the format.

The resurgence of vinyl records has also led to the revitalization of turntable technology and the celebration of the specialized skill of audio mastering for vinyl, ensuring the best possible listening experience for a new generation of vinyl aficionados.

2. The Importance Of Audio Mastering For Vinyl

The importance of audio mastering for vinyl cannot be overstated, as it is a critical step in ensuring optimal sound quality when playing a vinyl record.

Mastering for vinyl is a specialized skill that accounts for the unique demands of the format. Proper vinyl mastering is essential for achieving the best sound quality, maintaining the warmth and authenticity that vinyl enthusiasts seek, and ensuring a satisfying listening experience.

The growing interest in audio mastering for vinyl can be attributed to several factors that have contributed to the resurgence of vinyl records in recent years. As more artists choose to distribute their music on vinyl, the demand for skilled vinyl mastering engineers has increased. Here are some reasons behind this trend:

Reasons For The Resurgence Of Vinyl Records:

-

Unique Sound Quality:

Vinyl records are known for their distinct sound quality, often described as warm, rich, and authentic. The analog nature of vinyl captures the nuances of a recording more faithfully than digital formats, and many music enthusiasts appreciate this characteristic. Artists choose vinyl to provide their listeners with a unique and immersive listening experience. -

Tangibility And Collectability:

Vinyl records offer a tactile and visual appeal that digital formats lack. The larger album covers allow for more elaborate artwork, and the act of physically handling and playing a record creates a deeper connection to the music. Artists recognize the value of offering their fans a collectible item that can be cherished and displayed. -

Nostalgia And Retro Appeal:

Vinyl records evoke a sense of nostalgia and are often associated with the golden era of music. This retro appeal attracts not only older generations who grew up with vinyl but also younger audiences who are discovering the format for the first time. -

Higher Perceived Value:

Vinyl records often carry a higher price point than digital formats, reflecting the costs associated with their production and the perception of vinyl as a premium product. Artists can benefit from this higher perceived value, both in terms of revenue and enhancing their brand image. -

Differentiation And Marketing:

Releasing music on vinyl can help artists differentiate themselves in a crowded marketplace. Vinyl releases can generate buzz and media attention, while limited edition pressings and colored vinyl can create additional excitement and demand among fans. -

Supporting The Vinyl Community:

Many artists appreciate the sense of community surrounding vinyl records, from independent record stores to the dedicated fans who collect and cherish the format. By releasing music on vinyl, artists can contribute to the growth and sustainability of this passionate community.

As a result of these factors, more artists are choosing to distribute their music on vinyl, driving the demand for audio mastering specifically tailored to this unique format.

3. The Vinyl Mastering Process

The vinyl mastering process is a specialized and intricate series of steps that prepare an audio recording for reproduction on vinyl records. The stages involved in vinyl mastering, from the initial mix to the final lacquer cutting, are as follows:

The Vinyl Mastering Process:

- Preparing The Mix For Mastering:

Before the mastering process begins, the mixing engineer should provide a mix with appropriate headroom (usually around -6dB) and no limiting or excessive compression on the master bus. This allows the mastering engineer the necessary flexibility to shape the audio for vinyl. - EQ Adjustments And Dynamic Processing:

During this stage, the mastering engineer makes EQ adjustments and applies dynamic processing, such as compression and limiting, to balance the tonal and dynamic aspects of the audio. This ensures that the audio will translate well to the vinyl format, taking into consideration the limitations of the medium. - Track Sequencing And Spacing:

The engineer arranges the tracks in the desired order, considering the optimal side length for each side of the record. Proper sequencing can help minimize inner groove distortion by placing quieter tracks toward the end of each side. - Adjusting Levels And Maintaining Headroom:

The mastering engineer adjusts the overall levels of the audio to ensure that the loudness is appropriate for vinyl. Excessive loudness can cause issues with groove width and lead to distortion, so it is essential to maintain sufficient headroom. - Groove Width And Depth Considerations:

The engineer must take into account the groove width and depth when preparing the audio for cutting. Louder tracks or those with more low-end content require wider grooves, while quieter tracks need narrower ones. The depth of the grooves should also be optimized to ensure proper playback without skipping or other issues. - Cutting The Master Lacquer:

Using a specialized lathe, the mastering engineer cuts the audio onto a lacquer disc, which serves as the master from which all vinyl copies will be made. The lathe’s cutting stylus etches the audio waveform into the lacquer, creating a physical representation of the audio signal. - Quality Control And Test Pressings:

After the master lacquer is created, it is sent to a vinyl pressing plant, where a metal stamper is made from the lacquer. Test pressings are then created using the stamper, and these test pressings are evaluated for any issues or defects in the audio or the physical record itself. If any problems are found, adjustments can be made before the final pressing. - Final Pressing:

Once the test pressings are approved, the final vinyl records are pressed using the metal stamper, and the records are packaged and prepared for distribution.

Each stage of the vinyl mastering process plays a crucial role in ensuring the best possible sound quality and overall listening experience when the record is played on a turntable.

4. Key Vinyl Mastering Tools And Techniques

Key mastering tools and techniques used in vinyl mastering are designed to address the unique challenges and limitations of the vinyl format. Some of the essential tools and techniques include:

Key Mastering Tools And Techniques Used In Vinyl Mastering

- Equalizers (EQ):

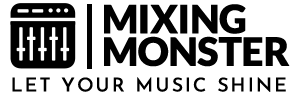

EQ adjustments are crucial in vinyl mastering to ensure a well-balanced frequency response. Vinyl is sensitive to low and high frequencies, and proper EQ adjustments can help manage bass content to avoid groove issues and control high frequencies to minimize distortion or sibilance.Additionally, mastering engineers may apply the RIAA equalization curve, which reduces low frequencies and boosts high frequencies during the cutting process, to ensure accurate frequency representation during playback. - Compressors:

Compression is used to control the dynamic range of the audio, which is important for vinyl due to its limited dynamic range compared to digital formats. Overly compressed audio can cause groove distortions or render a record unplayable.Mastering engineers use compression judiciously to balance the dynamics while maintaining sufficient headroom for the vinyl format. - Limiters:

Limiters are used in vinyl mastering to prevent excessive peaks that could cause distortion or damage the cutting stylus. Limiters help maintain consistent levels and prevent sudden spikes in loudness that could compromise the audio quality on vinyl.However, excessive limiting should be avoided, as it can result in a loss of dynamics and a less engaging listening experience. - De-Essers:

De-essers are essential for controlling sibilance (harsh “s” sounds) in the high-frequency range. Vinyl playback systems are more susceptible to high-frequency distortion, and mastering engineers use de-essers to selectively attenuate sibilant frequencies, ensuring clarity and minimizing distortion in the final product. - Stereo Imaging Tools:

Vinyl mastering may require the use of stereo imaging tools to adjust the stereo width of the audio, particularly in the low-frequency range. Wide stereo bass content can cause groove issues, and mastering engineers often narrow the stereo image of low frequencies or even sum them to mono to ensure proper groove spacing and prevent potential playback problems. - High-Pass Filters:

High-pass filters can be used to remove excessive low-frequency rumble or subsonic content that could cause issues with vinyl playback. By filtering out these frequencies, mastering engineers can prevent unnecessary groove excursions and ensure better tracking by the playback stylus. On average, high-pass filters are applied in the 20-70 Hz Region.

These mastering tools and techniques are employed with the specific needs of vinyl in mind, allowing engineers to optimize the audio for the format’s unique characteristics and limitations.

5. Limitations And Challenges Of Vinyl Recordings

The vinyl format, while cherished for its unique sound qualities and nostalgic appeal, has some inherent limitations and challenges that impact the audio reproduction and overall listening experience.

Mastering for vinyl differs from digital mastering in several key aspects, owing to the inherent physical limitations and characteristics of the vinyl format.

Limitations And Challenges Of Vinyl Recordings:

- Dynamic Range:

Digital formats can handle a wider dynamic range than vinyl, which has limitations due to the physical constraints of the grooves. Overly loud or compressed audio can result in groove distortions or even render a record unplayable. Vinyl mastering requires careful dynamic processing to accommodate these restrictions. - Bass Management:

Vinyl is sensitive to low-frequency content, particularly when it comes to stereo bass information. In vinyl mastering, engineers often need to manage bass frequencies carefully, sometimes by narrowing the stereo image of low-frequency content or applying a high-pass filter to remove excessive rumble. - High-Frequency Control:

Vinyl playback systems are more susceptible to high-frequency distortion, especially sibilance (harsh “s” sounds). Vinyl mastering engineers must address these issues using de-essers or other EQ techniques to maintain clarity and minimize distortion. - Track Sequencing And Spacing:

On vinyl, the groove spacing and track sequence can affect the sound quality. Louder tracks or tracks with more low-end content require wider grooves, while quieter tracks need narrower ones. Vinyl mastering engineers ensure proper spacing and sequencing to maximize sound quality without wasting space. - Inner Groove Distortion:

As the stylus moves toward the center of a vinyl record, the playback quality can deteriorate due to inner groove distortion. To mitigate this issue, vinyl mastering engineers often place quieter or less complex tracks toward the end of each side. - RIAA Equalization Curve:

Vinyl records adhere to the RIAA equalization curve, which reduces low frequencies and boosts high frequencies during the cutting process. During playback, the inverse curve is applied. Vinyl mastering engineers must work within this framework to ensure accurate frequency representation.

- Groove Spacing And Side Length:

The amount of audio that can be fitting onto each side of a vinyl record is limited by the groove spacing and side length. Longer sides can result in reduced audio quality, as the grooves need to be narrower and closer together, affecting the dynamics and bass response. - Surface Noise And Wear:

Vinyl records are susceptible to surface noise, such as pops, clicks, and crackles, which can be caused by dust, static, or pressing defects. Additionally, vinyl records can wear down over time, causing a degradation in sound quality with repeated play. - Tracking And Tracking Force:

The tracking ability of the playback stylus can be affected by the groove modulation, which can result in skipped grooves or mistracking. The tracking force applied by the tonearm also plays a role in the playback quality and potential wear on the record. - Storage And Handling:

Vinyl records require careful storage and handling to prevent warping, scratching, or other damage. They should be stored vertically, away from direct sunlight, and at a consistent temperature and humidity to ensure longevity and maintain sound quality.

Despite these limitations and challenges, vinyl records continue to be a popular format for their distinctive sound and nostalgic appeal.

Mastering engineers play a crucial role in overcoming these challenges by employing specialized techniques to optimize audio for the unique characteristics of vinyl.

6. The Role Of Test Pressings In Vinyl Distribution

Test pressings play a vital role in the vinyl production process, serving as a crucial quality control measure before the final pressing.

They are essentially the first few copies of a record made using the metal stamper, allowing the artist, label, and mastering engineer to evaluate the audio and physical quality of the vinyl before mass production begins.

The Role Of Test Pressings In Vinyl Distribution:

- Assessing Audio Quality:

Test pressings provide an opportunity to listen to the audio as it will be reproduced on the final vinyl record, ensuring that the mastering process has successfully translated the audio for the vinyl format. Any issues with the audio quality, such as distortion, sibilance, or noise, can be identified at this stage. - Identifying Physical Defects:

Test pressings allow for the detection of any physical defects in the record, such as non-fill (incomplete filling of the grooves during pressing), off-center pressings, or warping. Identifying and addressing these issues before the final pressing helps prevent the release of subpar vinyl records. - Evaluating Groove Spacing And Tracking:

Test pressings can help determine whether the groove spacing and sequencing are appropriate for the vinyl format. Issues such as skipping or mistracking can be detected and addressed before the final pressing. - Fine-Tuning The Cutting Process:

If any issues are identified during the evaluation of test pressings, the mastering engineer can make the necessary adjustments to the audio or the cutting process, ensuring the best possible sound quality for the final pressing. - Ensuring Consistency:

Test pressings can also be used to ensure consistency across different pressings and press runs. By comparing test pressings from different batches, potential variations in audio quality or physical properties can be detected and addressed.

Test pressings help ensure that the final product meets the expectations of the artist, label, and listeners, while also maintaining the high standards of the vinyl format.

7. Vinyl Pressing Plants And Vinyl Quality Control

Selecting a reputable vinyl pressing plant and maintaining stringent quality control measures are crucial aspects of vinyl production, as they directly impact the overall quality and consistency of the final product.

Reputable pressing plants use high-quality raw materials, such as virgin vinyl, to ensure a better-sounding and more durable final product. Inferior materials can result in noisy, subpar records that degrade quickly.

A reputable pressing plant maintains and regularly services their pressing equipment, ensuring consistent and accurate production. Well-maintained equipment reduces the chances of defects, such as warping, off-center pressings, or non-fill, resulting in higher-quality records.

Experienced technicians and operators at reputable pressing plants have the necessary skills and knowledge to handle the complexities of vinyl production. They can identify and address potential issues, ensuring a high level of quality control throughout the production process.

The implementation of stringent quality control measures and checking records for defects or inconsistencies throughout the production process are inevitable. This includes inspecting the metal stampers, monitoring the pressing process, and visually and audibly checking samples from each press run.

A reliable pressing plant can maintain consistency across multiple press runs, ensuring that the sound and physical quality of the records remain uniform. This is particularly important for artists and labels, as it helps maintain their reputation for delivering high-quality products.

Seasoned pressing plants are more likely to adhere to production timelines and maintain clear communication with clients, ensuring that any potential issues are addressed promptly and efficiently.

Selecting a reputable vinyl pressing plant and emphasizing quality control in vinyl production are essential steps in ensuring that the final product meets the expectations of artists, labels, and listeners.

By working with a reliable pressing plant and maintaining high standards throughout the production process, the unique appeal and sound quality of vinyl records can be preserved and enjoyed by fans worldwide.

8. Proper Vinyl Storage, Cleaning And Handling

Proper storage, handling, and cleaning of vinyl records are essential to maintain their quality and longevity. Here are some tips to help ensure your records remain in excellent condition:

How To Store, Clean And Handle Vinyl Records:

- Store Records Vertically:

Vinyl records should be stored vertically, with the records standing upright and not leaning at an angle. Stacking records horizontally can lead to warping and damage to the grooves over time. - Use Protective Sleeves:

Always store your records in protective inner and outer sleeves. Inner sleeves should be made of anti-static, non-abrasive materials, such as polyethylene or rice paper, to prevent scratches and reduce static build-up. Outer sleeves can be made of plastic or vinyl, providing additional protection against dust, moisture, and general wear. - Store In A Cool, Dry Environment:

Records should be stored in a consistent environment, away from direct sunlight, and at a stable temperature and humidity. Ideally, the temperature should be around 65-70°F (18-21°C), and the relative humidity should be between 45-50%. - Keep Away From Heat Sources And Direct Sunlight:

Exposure to heat and direct sunlight can cause warping and fading of the album artwork. Store your records in a shaded area, away from windows or heat-generating appliances. - Handle With Clean Hands And Care:

Always handle records by their edges or the label, avoiding contact with the grooves. Touching the grooves can transfer oils and dirt from your hands, potentially causing playback issues or damaging the record. - Clean Records Regularly:

Clean your records before and after playing them to remove dust, dirt, and fingerprints. Use a carbon fiber or anti-static brush to remove surface dust. For a deeper clean, use a record cleaning solution and a microfiber cloth or a dedicated record cleaning machine, following the manufacturer’s instructions. - Maintain Your Turntable:

Regularly clean and maintain your turntable, including the stylus, platter, and tonearm. A clean stylus ensures optimal sound reproduction and reduces wear on your records. Follow the manufacturer’s guidelines for cleaning and maintenance. - Store Records Away From Speakers And Vibrations:

Keep your records away from speakers and other sources of vibrations, as these can cause records to resonate, leading to possible damage or warping.

By following these tips for proper storage, handling, and cleaning of vinyl records, you can help maintain their quality and ensure their longevity, preserving the unique sound and charm of vinyl for years to come.

9. Vinyl Mastering: Reviving Analog Audio

In conclusion, audio mastering for vinyl is an essential and specialized process that ensures the optimal sound quality and listening experience for vinyl enthusiasts.

With the resurgence of vinyl records in recent years, more artists and labels are recognizing the importance of vinyl mastering in delivering a product that meets the expectations of listeners.

The process involves unique considerations, such as addressing the format’s inherent limitations and challenges, using specialized mastering tools and techniques, and working closely with reputable pressing plants to ensure consistent quality.

Test pressings play a critical role in evaluating the audio and physical quality of a record before mass production, while proper storage and handling of vinyl records contribute to their longevity and preservation.

By understanding and implementing the principles of audio mastering for vinyl, mastering engineers, artists, and labels can create high-quality records that capture the warmth, authenticity, and nostalgia of the vinyl format, providing an unparalleled listening experience for consumers.